Are Diecast Toys Safe Overview

The question of whether diecast toys are safe is a crucial one for parents, collectors, and anyone interested in these miniature marvels. Diecast toys, known for their intricate detail and durability, are often cherished possessions. However, their construction, involving various materials and intricate designs, raises important safety considerations, especially for children. This guide provides a comprehensive overview of the safety aspects of diecast toys, delving into material composition, potential hazards, and essential safety measures. Understanding these factors ensures that the joy of playing with or collecting diecast toys is matched by the assurance of safety.

Material Composition

The materials used in diecast toys play a significant role in their safety profile. These toys are primarily made from a combination of metals and non-metal components, each carrying its own set of safety considerations. The primary metal used is typically zinc alloy, sometimes mixed with small amounts of aluminum or magnesium. The non-metal parts include plastics for tires and windows, and sometimes rubber or plastic for other details. Understanding the properties and potential hazards associated with each material is key to assessing the overall safety of a diecast toy.

Metals Used

Zinc alloy is the most common metal used in diecast toy manufacturing. It’s chosen for its ability to take on intricate shapes and its durability. The alloy often includes small amounts of other metals like aluminum and magnesium to enhance properties like strength and corrosion resistance. The quality of the metal alloy and its processing is crucial in determining the safety of the final product. High-quality alloys and careful manufacturing processes are vital to avoid potential issues such as the release of harmful substances or structural weaknesses in the toy.

Potential Hazards of Metals

While zinc alloy itself is generally considered safe, potential hazards can arise from manufacturing processes and the presence of impurities. Exposure to lead, cadmium, or other heavy metals during the production or as contaminants in the alloy is a serious concern. Ingestion of these metals can lead to various health problems, especially in children. Therefore, stringent quality control and adherence to safety standards are vital. Checking for certifications and ensuring that the toy meets safety regulations can help mitigate these risks. The paint used on the toys may also contain these harmful substances if not manufactured according to strict standards.

Non-Metal Components

Non-metal components, such as plastics and rubber, are also used in diecast toys. These parts, including tires, windows, and various decorative elements, can pose different safety challenges. The plastics used must be free from harmful chemicals such as phthalates, which are used as plasticizers and can be dangerous if ingested. Similarly, the paint on these parts must be non-toxic and resistant to chipping or flaking. It’s important to be aware of the types of plastics used and to ensure that they meet safety standards such as EN71 and ASTM, which regulate the use of these materials in toys. The overall safety of a diecast toy relies on the safe and careful use of both metal and non-metal components.

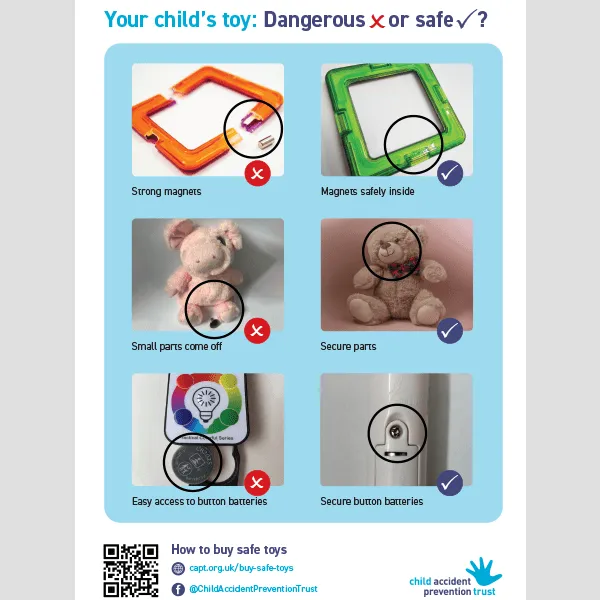

Choking Hazards

One of the primary safety concerns with diecast toys, especially for young children, is the potential for choking hazards. This risk arises from small parts that can detach or break off, as well as the overall size and design of the toy. These small pieces, if swallowed or inhaled, can obstruct a child’s airway, leading to serious health consequences. Careful attention to the design and construction of the toys, combined with appropriate age recommendations, is essential in mitigating this risk. Parents and caregivers need to be vigilant about the state of the toys, and to regularly inspect them for any signs of damage or wear that could lead to small parts becoming loose.

Small Parts and Design

Small parts are a significant concern in diecast toys. These can include wheels, mirrors, small decorative pieces, or even the toy’s axles. The design of the toy should minimize the presence of small, easily removable parts. Manufacturers must ensure that any detachable components are securely attached and can withstand reasonable handling by children. The toy’s overall construction should also consider the child’s interaction with the toy. Smooth edges, secure attachments, and the avoidance of small, easily-detached pieces are critical design considerations to prevent choking hazards.

Age Appropriateness

Age recommendations provided by the manufacturer are essential guidelines. These recommendations consider the size, design, and potential hazards of the toy relative to a child’s developmental stage. Toys intended for older children may contain small parts that pose a choking risk to younger children. Parents and caregivers should carefully follow the age recommendations, and avoid giving toys that are not age-appropriate. Always consider a child’s behavior and how they play with their toys when determining if a toy is appropriate. This is an essential step in ensuring safety.

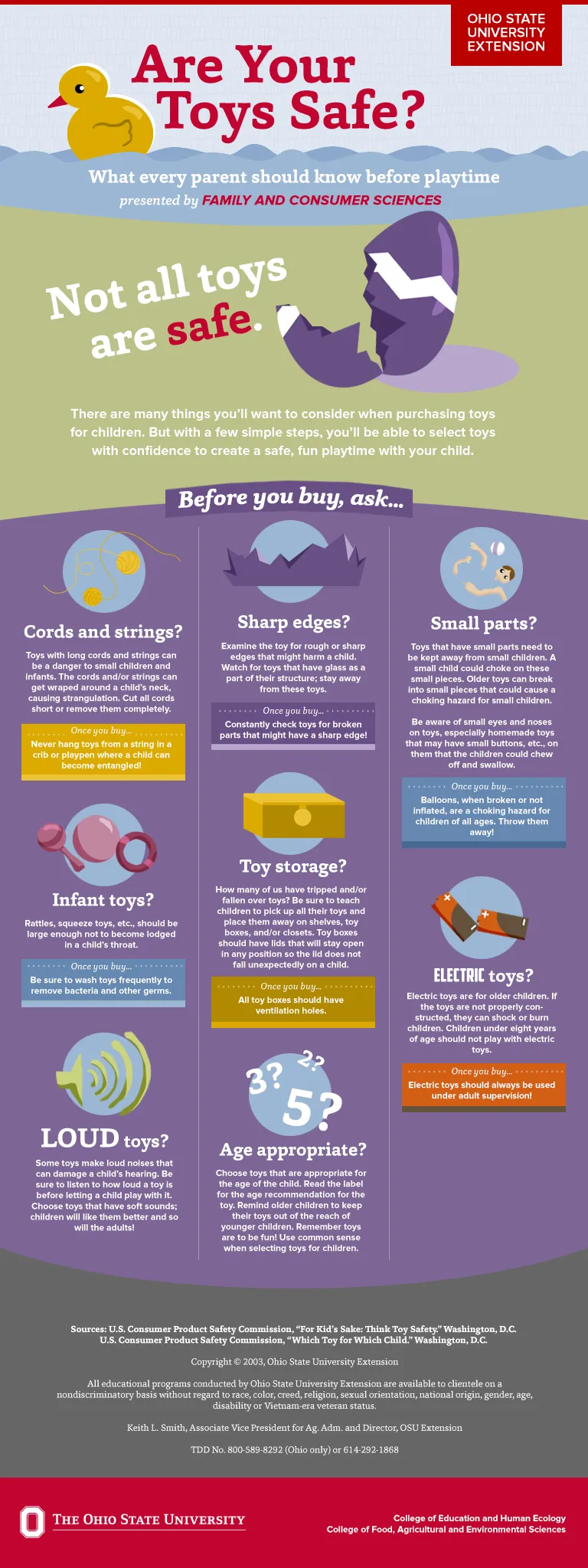

Sharp Edges and Points

Another safety aspect to consider in diecast toys is the presence of sharp edges and points. Poorly finished edges, protrusions, or sharp corners can pose a risk of cuts or other injuries, especially for young children. These hazards can arise during the manufacturing process if not properly addressed. The design and finishing of the toy play an important role in minimizing these risks. Manufacturers should ensure that all edges are smooth, rounded, and free from any sharp points that could potentially cause harm. Regular inspection of the toys is also critical to identify any damage or wear that could expose sharp edges.

Manufacturing Quality Control

Quality control is critical in ensuring that diecast toys are safe from sharp edges. Manufacturers must implement robust quality control measures throughout the production process. This includes inspecting the raw materials, monitoring each step of the manufacturing process, and conducting final inspections to identify and rectify any defects. Proper quality control ensures that all edges are properly finished, and there are no sharp protrusions that could cause injury. Regular audits and checks are important to maintain safety standards and ensure that toys meet all required safety guidelines.

Testing and Certifications

Diecast toys should undergo rigorous testing and certification processes. This helps to verify that they meet established safety standards. Certifications such as EN71 (European Standard) and ASTM (American Society for Testing and Materials) provide assurance that the toy has been tested for a variety of safety aspects, including mechanical properties, flammability, and the presence of harmful chemicals. Checking for these certifications on the toy packaging is an easy way to assess its safety. These certifications ensure that the toys meet international standards and pose minimal risk to children.

Lead Paint Concerns

Lead paint is a significant historical concern for toy safety, and although regulations have significantly reduced its use, it remains a risk to be aware of. Lead is a toxic substance that can be harmful, especially to children. Ingestion of lead paint can lead to developmental problems and other serious health issues. Modern regulations, such as those in the United States and Europe, strictly limit the use of lead in paint and coatings for toys. However, older diecast toys or those from countries with less strict regulations may still pose a risk. Regular inspection for any signs of paint chipping or wear, along with careful consideration of a toy’s age and origin, can help in minimizing this risk.

Regulations and Standards

Various regulations and standards are in place to govern the safety of toys, including diecast models. These regulations, such as those set by the Consumer Product Safety Commission (CPSC) in the United States, and EN71 in Europe, outline specific requirements for materials, design, and testing. These standards restrict the use of hazardous materials like lead and phthalates and provide guidelines for the construction of toys to minimize hazards like choking. Manufacturers must adhere to these regulations, ensuring that toys meet a minimum safety level before they are released for sale. Keeping up-to-date on the relevant safety standards and regulations is critical to assess the safety of diecast toys.

Checking for Safety Labels

When purchasing diecast toys, look for specific safety labels and certifications. These labels indicate that the toy has been tested and meets required safety standards. Common certifications include EN71, ASTM, and the CE mark. These certifications serve as an assurance that the toy has undergone testing and meets specific safety criteria. Additionally, check for age recommendations, which are crucial in determining whether the toy is appropriate for the child. These labels and certifications offer essential information to make informed decisions. They are also an easy and straightforward method to assess the safety of a diecast toy before making a purchase.

How to Choose Safe Diecast Toys

Choosing safe diecast toys involves several key considerations, from examining the toy’s construction to understanding its intended use and the child’s age. By taking a few extra steps, parents and caregivers can ensure that they are selecting toys that provide both entertainment and safety. This includes careful evaluation of the toy’s design, the materials used, and any certifications it may carry. Awareness of potential hazards and a proactive approach to safety can significantly reduce the risk of injuries or other issues associated with diecast toys.

Check for Durability

Assessing the durability of a diecast toy is important. Durable toys are less likely to break apart and create small parts that could be a choking hazard. Check for sturdy construction, solid connections, and the quality of materials used. Avoid toys with flimsy parts or those that seem easily breakable. Consider where the toy will be used and the type of play it will endure. A well-made diecast toy will withstand the wear and tear of regular play, providing lasting enjoyment and minimizing safety risks. Regularly inspect the toy for any signs of damage and replace it if necessary.

Read Reviews and Ratings

Reading reviews and ratings from other customers offers valuable insights into a diecast toy’s safety and quality. These reviews often highlight real-world experiences, including any potential issues or hazards that users have encountered. Look for reviews that mention durability, the presence of small parts, and any safety concerns. Websites such as Amazon, specialized toy review sites, and consumer reports can provide these insights. Consider both positive and negative feedback to make a balanced assessment of the toy’s overall safety profile. Reviews provide a good overview of the toy and its long-term safety and use.

Storage and Maintenance

Proper storage and maintenance of diecast toys are essential to maintaining their safety over time. These steps help preserve the toy’s condition and prevent the development of potential hazards. Following these practices ensures that toys remain in good condition and continue to provide safe entertainment. Proper storage practices, regular inspections, and maintenance can significantly prolong the lifespan of a diecast toy and minimize any potential risks. Careful attention can help maintain the toys’ safety over time.

Proper Storage Practices

Storing diecast toys correctly is important to prevent damage and maintain their safety. Keep toys in a dry, clean place, away from direct sunlight and extreme temperatures. This helps prevent corrosion, fading, and degradation of the materials. Consider using storage containers, shelves, or display cases to protect the toys from dust and potential hazards. Organize toys by size or type, and ensure that any storage solutions are child-safe, with no sharp edges or potential tripping hazards. Proper storage not only preserves the condition of the toys but also minimizes the risk of accidents and injuries.

Regular Inspection and Maintenance

Regular inspection and maintenance are essential for maintaining the safety of diecast toys. Periodically check toys for any signs of damage, wear and tear, or loose parts. Look for any chipping paint, broken components, or sharp edges. Perform basic maintenance, such as cleaning the toys with a soft cloth and mild soap to remove dust and dirt. If any damage is detected, repair the toy if possible or, if it is unsafe, remove it from use. By taking these proactive steps, you can ensure that diecast toys remain safe and enjoyable for years to come. A well-maintained toy is a safe toy.