What are Resin Model Cars?

Resin model cars are meticulously crafted miniatures, often prized by collectors for their high level of detail and accuracy. They are typically made from a mold filled with liquid resin, which then hardens to create the car body. The resin allows for intricate detailing, resulting in models that closely replicate the real-world vehicles they represent. These models are often produced in limited quantities, enhancing their collectibility and value. Resin cars are known for their smooth finishes and the ability to capture complex curves and fine features that might be challenging to reproduce using other materials. They are favored by enthusiasts who appreciate the artistry and precision involved in model car creation. Resin models typically come with a higher price tag compared to their diecast counterparts due to the more complex manufacturing process and the premium materials used.

The Manufacturing Process of Resin Cars

The manufacturing process for resin model cars involves several steps. First, a master model is created, often using CAD software and 3D printing. This master model is then used to create molds. Liquid resin is carefully poured into these molds and allowed to cure and harden. Once the resin has set, the model is removed from the mold, and any excess material is trimmed. The model then undergoes meticulous detailing, including painting, applying decals, and adding small parts such as lights, mirrors, and interior components. The paintwork is often done by hand to ensure a flawless finish. Finally, the model is carefully inspected and packaged for sale. The entire process is labor-intensive, which contributes to the higher cost of resin models. Each step requires skilled craftsmanship to ensure the final product accurately reflects the original vehicle and meets the high standards collectors expect. The meticulous attention to detail during manufacturing makes resin cars highly sought-after items.

Advantages of Resin Model Cars

Resin model cars boast several advantages that make them appealing to collectors. One of the primary benefits is the high level of detail achievable. The resin material allows for intricate designs and fine features that are difficult to replicate with diecast methods. This includes sharp edges, complex curves, and detailed interior components. Resin cars often have smoother finishes and a more refined appearance, enhancing their realism. They tend to have thinner body panels and more accurate proportions compared to diecast models. Another significant advantage is the ability to produce limited-edition runs. These limited productions add to the exclusivity and collectibility of the models, increasing their value over time. Resin models are favored by collectors who appreciate the craftsmanship and attention to detail and are willing to pay a premium for a superior-quality miniature.

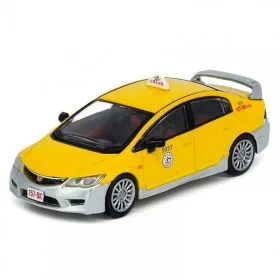

Detailed Exterior Features

The exterior features of resin model cars are often meticulously detailed, making them highly realistic. The resin material allows for sharp edges, precise panel lines, and accurate representations of body curves. Manufacturers can replicate complex features such as spoilers, grilles, and aerodynamic elements with exceptional accuracy. Paint finishes are typically of a high quality, often including multiple layers and clear coats to provide a deep, glossy appearance. Decals are applied with precision and sealed to prevent damage, ensuring that the car’s branding and markings are faithfully reproduced. The use of photo-etched parts for details like badges and grilles adds another layer of refinement. Overall, the exterior of resin models is designed to closely resemble the actual vehicle, making them highly desirable for collectors.

Interior Detailing

Interior detailing in resin model cars is a major factor in their appeal. Manufacturers pay close attention to the dashboard, seats, steering wheel, and other interior components, aiming for a high degree of accuracy. The use of different materials and colors helps to create a realistic interior environment. Resin models often feature detailed instrument panels, complete with gauges and dials. Seats are meticulously crafted, with accurate stitching patterns and textures. The steering wheel and gear shift are also replicated with precision. The interior detailing extends to the door panels, which include armrests, window controls, and speaker grilles. Some models even include features like seatbelts and carpets, further enhancing the realism. The level of interior detail contributes significantly to the overall value and collectibility of the resin model cars.

Disadvantages of Resin Model Cars

While resin model cars offer numerous advantages, they also have some drawbacks. One of the primary disadvantages is their fragility. Resin is a more brittle material compared to diecast metal, making resin cars more susceptible to damage from impacts or drops. This can be a significant concern for collectors who handle their models frequently or display them in high-traffic areas. Another potential drawback is the higher cost. The detailed manufacturing process, including the use of premium materials and hand-finishing, results in a higher price point compared to diecast models. This can make resin cars less accessible to some collectors. Furthermore, resin cars typically have less play value due to their delicate nature. They are better suited for display than for handling by children. Ultimately, the disadvantages of resin models should be considered when deciding whether they are the right choice for your collection.

Fragility and Durability

One of the main disadvantages of resin model cars is their fragility. The resin material is more susceptible to damage from impacts or drops compared to the metal used in diecast models. This means that resin cars can easily chip, crack, or break if mishandled. Collectors must be cautious when handling resin models and should avoid placing them in areas where they are likely to be knocked over or bumped. While the level of detail is often exquisite, the delicate nature of resin cars limits their play value, making them less suitable for young children. Proper storage and display are essential to protect resin models from damage and preserve their value. Collectors should also be aware that resin can be sensitive to extreme temperatures, which can affect the model’s structural integrity. Therefore, it’s crucial to handle resin models with care to prevent any potential damage.

Cost Considerations for Resin Cars

The higher cost is a key factor to consider when purchasing resin model cars. The meticulous manufacturing process, which involves detailed handcrafting and the use of high-quality materials, contributes to the premium price. The complexity of the mold-making, resin pouring, detailing, and finishing all require skilled labor, driving up production costs. Limited production runs, often associated with resin models, also add to their value. These factors mean that resin cars typically cost significantly more than their diecast counterparts. This higher price point makes resin models a more significant investment for collectors. Budget plays a crucial role in deciding whether resin or diecast models are the better choice. Collectors should carefully assess their budget before purchasing to ensure they are making a purchase that aligns with their financial goals. While the superior detailing and build quality justify the higher cost for many collectors, it is important to manage expectations and make informed decisions.

What are Diecast Model Cars?

Diecast model cars are a staple in the model car world, known for their durability and affordability. They are made by injecting molten metal, typically zinc alloy, into a mold. This process allows for mass production and cost-effectiveness. Diecast cars are celebrated for their robust construction, which makes them suitable for handling and play. While the level of detail may not always match that of resin models, diecast cars still offer a high degree of accuracy, with detailed exteriors and interior components. They are accessible to a broad audience due to their lower price point. Diecast cars are often available in a wide range of makes, models, and scales, appealing to diverse collector interests. They have become a popular choice for enthusiasts of all ages, providing a reliable and enjoyable way to collect miniature vehicles. Diecast models often include features like opening doors, hoods, and trunks, which adds to their playability and collectibility.

The Manufacturing Process of Diecast Cars

The manufacturing process for diecast model cars is highly automated and designed for mass production. It starts with creating metal molds, which are used to cast the car bodies. Molten metal, usually a zinc alloy, is injected into the molds under high pressure. Once the metal has cooled and solidified, the model is removed from the mold, and any excess material is trimmed. The car bodies then undergo a series of finishing steps, including polishing, painting, and applying decals. Details like lights, grilles, and interior components are added, often using plastic or other materials. The assembly process is optimized for efficiency, allowing manufacturers to produce large volumes of cars at a relatively low cost. Diecast models also have moving parts, such as opening doors, hoods, and trunks, which are integrated during assembly. Finally, the completed models are inspected, packaged, and prepared for distribution. This manufacturing process results in durable and affordable model cars.

Advantages of Diecast Model Cars

Diecast model cars have several advantages, making them a popular choice for collectors of all ages. The primary advantage is their durability and sturdiness. Diecast cars are made from metal, which makes them more resistant to damage compared to resin models. They can withstand rough handling and are less likely to break or chip if dropped. Another significant advantage is their cost-effectiveness. The mass-production process of diecast cars allows manufacturers to offer them at a lower price point than resin models. This affordability makes diecast cars accessible to a broader audience, from casual collectors to serious enthusiasts. Diecast models are also widely available, with a vast selection of makes, models, and scales to choose from. This diversity means collectors can easily find models that align with their interests and preferences. Finally, diecast cars often have features like opening doors, hoods, and trunks, enhancing playability and adding to their collectibility.

Durability and Sturdiness

The superior durability and sturdiness of diecast model cars are major benefits. Made from a metal alloy, these models can withstand the bumps and bruises of handling, making them ideal for both collectors and children. Diecast cars are much less susceptible to damage from accidental drops or impacts compared to resin models, which are more brittle. This durability makes diecast cars a practical choice for those who want to enjoy their models without constantly worrying about breakage. The sturdy construction also means that diecast models are more resistant to wear and tear over time. They can handle repeated handling and display without significant damage. This durability contributes to the long-term value of diecast cars and makes them a reliable investment for collectors. The resilience of diecast cars ensures that they can remain in good condition for years, providing lasting enjoyment and collectibility.

Cost Effectiveness of Diecast Cars

Cost effectiveness is a significant advantage of diecast model cars. The mass-production methods used to create diecast models contribute to lower manufacturing costs, which are then passed on to the consumer. This makes diecast cars much more affordable than resin models, which involve more labor-intensive and specialized processes. The lower price point makes diecast cars accessible to a broader audience. This includes casual collectors, children, and those new to the hobby. Affordability allows collectors to build larger and more diverse collections without breaking the bank. The cost effectiveness also means that diecast models are a good option for gifts or as an entry point into the world of model car collecting. The ability to purchase a wide range of models at reasonable prices makes diecast cars a practical and enjoyable choice for many enthusiasts.

Disadvantages of Diecast Model Cars

Despite their many advantages, diecast model cars do have some drawbacks. One of the primary limitations is the level of detail, which may not always match the precision of resin models. The manufacturing process for diecast cars can restrict the ability to capture extremely fine details and complex shapes. This means that some of the intricate features seen in resin models might be simplified in diecast versions. Another potential drawback is the weight, as diecast cars are heavier than resin models due to the metal construction. The weight can be a factor for collectors who display their models in areas with limited support. Diecast cars can also be prone to paint imperfections or minor flaws in the manufacturing process, although quality control has improved over time. Despite these disadvantages, the benefits of durability, affordability, and widespread availability often outweigh the minor drawbacks for many collectors. The overall value proposition of diecast models remains strong.

Less Detailed Finishes

One of the primary disadvantages of diecast model cars is that they typically exhibit less detailed finishes compared to resin models. The mass-production methods used in diecast manufacturing can limit the level of intricacy achievable in the final product. Features such as fine panel lines, intricate grilles, and subtle interior details may be simplified. The paint finishes on diecast models may also have a slightly thicker appearance and may not always achieve the same depth and realism as the finishes on resin models. However, diecast models are constantly improving, with manufacturers striving to enhance their detail and accuracy. While they may not reach the same level of precision as resin models, diecast cars still provide a high degree of realism and are constantly evolving. This makes them a valuable option for collectors seeking quality and affordability.

Resin vs Diecast Model Cars Choosing the Right One

Choosing between resin and diecast model cars depends on individual priorities, budget, and collecting preferences. Resin cars are ideal for collectors who prioritize high levels of detail, accuracy, and exclusivity. If you appreciate meticulous craftsmanship, are willing to invest more, and primarily display your models, resin cars might be the better choice. They are perfect for showcasing the fine features of a specific car. Diecast cars, on the other hand, are great for those who value durability, affordability, and a wide variety of models. If you want models that can withstand handling, are on a budget, or want a broader selection of cars, diecast models will be your best option. Consider your collecting goals and what you want to gain from the hobby when making your choice. Ultimately, the ‘better’ option is the one that meets your individual needs and brings you the most enjoyment. Many collectors enjoy both types of models, appreciating the unique strengths of each.

Factors to Consider for Collectors

Several factors influence the decision of collectors regarding resin and diecast model cars. The first is the level of detail. Resin cars often excel in this area, offering more intricate features and accurate representations of the real vehicles. The budget is also an important factor, as resin models typically come with a higher price tag. Durability and play value are essential considerations, especially if the models will be handled by children. Display and handling preferences affect the choice, as resin models require careful handling and are best suited for display, while diecast cars offer more robustness. The rarity and exclusivity of the models play a significant role in collecting, as limited-edition resin models often become highly sought-after. Collectors should also consider the availability of models and the specific makes and models they want to collect. Ultimately, the decision depends on a combination of personal preferences, collecting goals, and financial considerations.

Budget and Affordability

Budget plays a crucial role in deciding between resin and diecast model cars. Resin models are generally more expensive due to their detailed manufacturing processes and high-quality materials. The price can vary widely depending on the size, brand, and level of detail. Diecast cars, being produced through mass-production techniques, are typically more affordable. They provide collectors with an accessible way to build a collection without a significant financial commitment. Collectors should set a budget beforehand to ensure they can purchase the models they want without overspending. Considering the long-term value of the models is also important. Limited-edition resin models may increase in value over time, making them a potential investment, while diecast models provide a cost-effective entry into the hobby. Evaluate your budget to make sure it aligns with your goals and collecting preferences. Balancing quality and affordability is key to a satisfying collecting experience.

Display and Handling

The way you plan to display and handle your model cars greatly influences your choice between resin and diecast. Resin cars, with their delicate construction, are best suited for display purposes. They require careful handling and should be stored in a safe place away from potential damage. Resin models look great in a glass cabinet or display case. Diecast cars, on the other hand, are more durable and can withstand more handling. They are a good option if you like to take the cars out and play with them. If you have children, diecast models are often a safer choice because they are less likely to break or chip. Your display preferences also come into play. Resin cars offer the exquisite details that look amazing on display, while diecast models, with their durability, offer you freedom to handle them. Consider where and how you plan to display your collection before making a decision. Your desired level of interaction with the models will guide your choice.

Conclusion

The choice between resin and diecast model cars is ultimately a matter of individual preference and collecting goals. Resin cars offer unmatched levels of detail and are perfect for collectors who value precision and exclusivity, and who are willing to invest more. Diecast cars provide durability, affordability, and a wide selection, appealing to a broad range of collectors. Consider your budget, display preferences, and the level of detail you desire when making your decision. Remember that the ‘better’ choice is the one that brings you the most enjoyment and aligns with your personal collecting journey. Both resin and diecast model cars offer unique advantages, and many collectors appreciate both, adding variety and interest to their collections. So, decide which factors are most important to you, and choose the model cars that make you happy. Happy collecting!